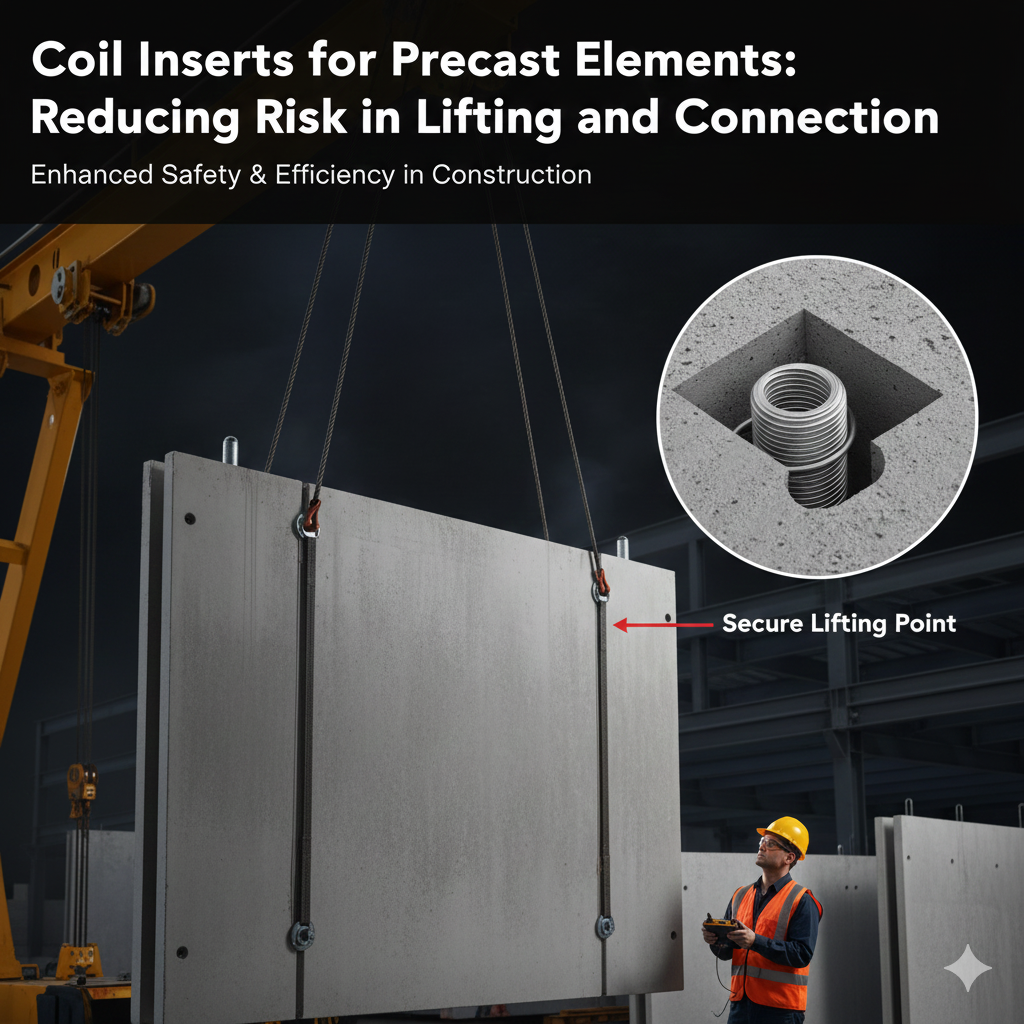

Coil Inserts for Precast Elements: Reducing Risk in Lifting and Connection

In precast construction, problems rarely start with concrete strength.

They start when force is transferred incorrectly.

A wall panel that tilts during lifting, a façade element that needs on-site drilling, or a connection that loosens after installation—these are not random failures. In many cases, they trace back to one overlooked component: the coil insert.

Not because the insert failed outright, but because it was not selected or positioned with the full project lifecycle in mind.

Coil Inserts Are a Structural Decision, Not a Minor Accessory

Once a coil insert is cast into concrete, it becomes permanent.

There is no second chance to adjust embedment depth, thread alignment, or load direction without damaging the element itself.

That makes insert selection a front-loaded decision with downstream consequences—affecting lifting safety, installation speed, and even long-term serviceability.

In practice, treating coil inserts as interchangeable hardware is one of the most common sources of avoidable site risk in precast projects.

Where Coil Insert Problems Usually Appear on Site

Most issues do not show up in drawings or factory inspections. They surface under real conditions—when time pressure and load come together.

Typical scenarios include:

-

slight rotation of inserts during lifting, causing off-axis load

-

thread deformation after repeated engagement

-

local concrete cracking near insert locations

-

mismatch between insert thread profile and lifting hardware

Individually, these issues may seem manageable. Collectively, they lead to extra crane time, rework, and safety controls that were never part of the original plan.

Geometry Controls Load Transfer More Than Nominal Capacity

Two inserts may share the same rated tensile load, yet behave very differently in concrete.

The difference often lies in geometry:

-

thread profile affects how evenly load is transferred

-

embedment length determines whether stress disperses or concentrates

-

anchoring tail design influences resistance to pull-out and rotation

Inserts that distribute force gradually into the concrete body reduce the risk of edge breakout and micro-cracking during dynamic lifting. Those that concentrate stress near the surface tend to pass lab tests—but struggle under real lifting conditions.

This is why experienced precast engineers prioritize load behavior, not just load ratings.

Material Selection Is About More Than Corrosion

Material choice is frequently framed as a corrosion discussion.

In reality, it is also about thread durability and reuse reliability.

| Material option | Practical implication in precast projects |

|---|---|

| Carbon steel | Suitable for controlled environments and single-use lifting |

| Zinc-plated steel | Balanced option for general outdoor exposure |

| Stainless steel (304 / 316) | Preferred where repeated use, humidity, or façade exposure is expected |

Repeated lifting, storage, and reinstallation cycles place cumulative stress on threads. Materials that maintain thread integrity over time reduce uncertainty and extend safe service life.

Manufacturers such as Jingle validate insert performance through repeated load and corrosion exposure testing, not just one-time tensile checks, to reflect actual site conditions.

How Insert Choices Affect Installation Speed

One underappreciated role of coil inserts is positional control during installation.

Accurate insert placement allows crews to fine-tune alignment mechanically. Poor placement forces manual adjustment—slotting holes, grinding concrete edges, or drilling after curing. These actions are slow, risky, and difficult to control.

In large-scale precast projects, small alignment inefficiencies multiply quickly, turning minor insert issues into schedule delays.

Coil Inserts Across the Precast Lifecycle

The real value of a coil insert becomes clear when viewed across the entire project timeline:

| Project stage | Role of the coil insert |

|---|---|

| Casting | Enables predictable embedment and reinforcement coordination |

| Demolding & lifting | Transfers dynamic load safely into concrete |

| Transportation | Resists vibration and shifting forces |

| Installation | Supports controlled alignment and fastening |

| Service life | Allows future access, adjustment, or retrofit |

Few components influence so many stages with such a small physical footprint.

Cost Is Rarely in the Insert Itself

From a procurement standpoint, coil inserts represent a small percentage of total project cost.

From a risk standpoint, they influence some of the most expensive failure modes.

Poor insert selection often results in:

-

additional crane operations

-

damaged panels

-

delayed sequencing

-

increased safety oversight

When evaluated against these outcomes, higher-quality inserts are less a cost increase than a form of risk containment.

Building Predictability Into Precast Systems

Reliable precast construction depends on predictability.

Coil inserts contribute to that predictability when their geometry, material, and placement strategy are aligned with real load paths and site conditions.

When specified early and verified properly, they become silent contributors—rarely noticed, rarely discussed, and rarely responsible for problems.

That is exactly how structural components should behave.

Conclusion: Small Components, Disproportionate Impact

Coil inserts may disappear once concrete sets, but their influence remains throughout the life of a precast element. They shape how panels are lifted, how accurately they are installed, and how confidently structures perform over time.

Choosing them well does not draw attention.

Choosing them poorly makes attention unavoidable.

To explore more precast connection and fastening solutions, visit the Jingle home page or reach out via the contact page for application-specific technical guidance.