How Connecting Loops Simplify Precast Wall Installation in Construction

Precast concrete wall panels are widely used in modern construction for their efficiency, durability, and design versatility. However, securely connecting these panels to each other or to columns can be a challenge. This is where connecting loops come into play, offering a practical and reliable solution to streamline the installation process while ensuring structural integrity. In this blog post, we’ll explore what connecting loops are, how they work, and why they’re a game-changer for precast construction.

What Are Connecting Loops?

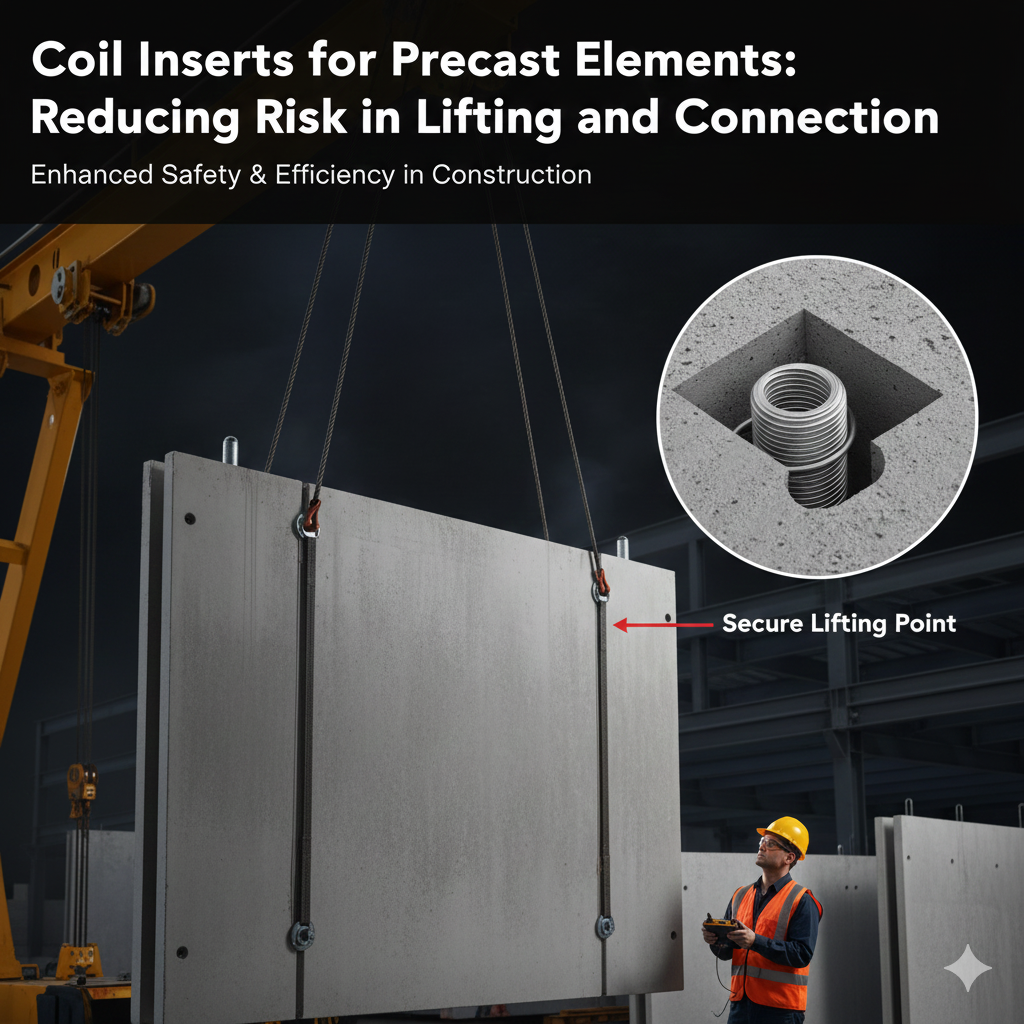

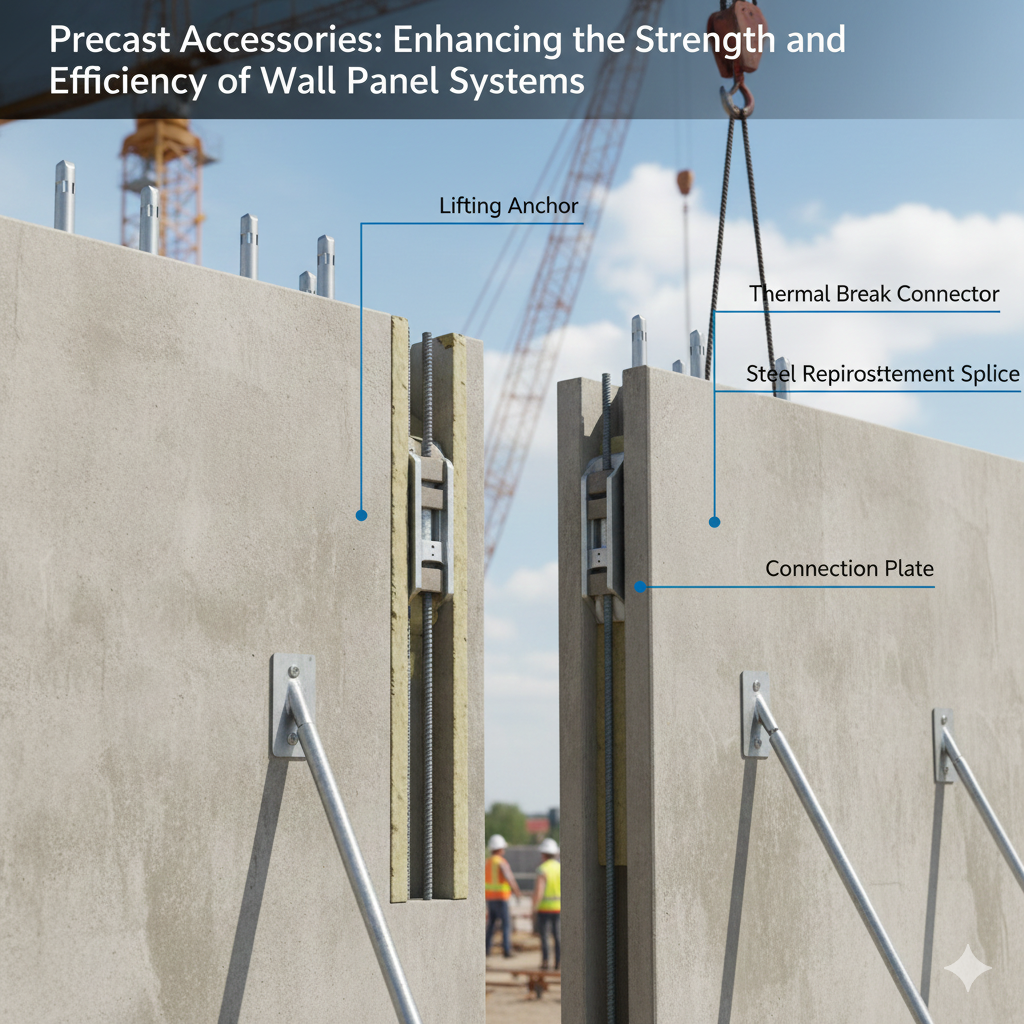

Connecting loops are single-wire loops designed to connect precast wall panels to each other or to columns. Encased in a protective box, these loops are embedded into the precast elements during manufacturing. The system is designed for simplicity: after the panels are cast and the formwork is removed, the loops can be easily accessed and bent into position, creating a secure connection point for adjoining elements.

Available in standard wire lengths of 60 mm, 80 mm, 100 mm, 120 mm, and 140 mm, these loops accommodate joint depths ranging from 80 mm to 140 mm, making them adaptable for various project needs.

How Connecting Loops Work in Construction

The installation process using connecting loops is straightforward and efficient, reducing complexity on-site. Here’s a step-by-step overview:

-

Pre-Installation Setup: Before casting the precast elements, the loop boxes are fixed onto the formwork at predetermined intervals. These intervals are calculated to ensure the loops can effectively bear shear loads between panels or between a panel and a column.

-

Formwork Removal and Loop Preparation: Once the concrete has cured and the formwork is removed, the protective tape covering the wire loops is peeled off. The loops are then bent out from their box using a hammer or a pin, making them ready for the connection process.

-

Panel Installation: The precast wall panels are erected and supported according to the construction plans. The bent-out loops from adjacent panels (or a panel and a column) are aligned to face each other.

-

Securing the Connection: A vertical rebar is inserted through the aligned loops, creating a strong linkage that ensures structural stability. The horizontal alignment of the loops is checked to confirm proper positioning.

-

Final Grouting: With the panels in place and the loops connected, the formwork for the joint is completed. Concrete grout is then poured or pumped into the joint, encasing the loops and rebar to finalize the connection.

This method ensures a robust and durable connection that can withstand the structural demands of the building.

Why Choose Connecting Loops?

Connecting loops offer several advantages that make them a preferred choice in precast construction:

-

Ease of Use: The system’s design simplifies the installation process. Removing the tape and bending the loops is quick and requires minimal tools, saving time on-site.

-

Structural Reliability: By using a vertical rebar through the loops and grouting the joint, the connection achieves high shear load resistance, ensuring the stability of the structure.

-

Versatility: With multiple loop lengths available, these loops can be used in a variety of joint configurations, accommodating different panel thicknesses and joint depths.

-

Efficiency in Construction: The straightforward installation process reduces labor time and potential errors, making the overall construction timeline more efficient.

Applications in Precast Construction

Connecting loops are ideal for a wide range of precast concrete applications, including:

-

Residential Buildings: Connecting precast wall panels in multi-story residential structures.

-

Commercial Projects: Joining panels or columns in office buildings, warehouses, or retail spaces.

-

Industrial Facilities: Ensuring secure connections in large-scale industrial constructions where precast elements are commonly used.

Their ability to handle shear loads makes them particularly valuable in projects where structural integrity is critical, such as in seismic zones or high-rise buildings.

Conclusion

Connecting loops are a smart solution for modern precast construction, combining ease of installation with reliable performance. By simplifying the connection process and ensuring strong, stable joints, they help contractors save time and reduce complexity on-site while maintaining the structural integrity of the building. Whether you’re working on a residential, commercial, or industrial project, connecting loops provide a dependable and efficient way to connect precast elements, making them a valuable tool in any construction professional’s toolkit.