OEM fastener customization is a critical solution for industries facing challenges with standard components, offering tailored precision that enhances performance and reliability. In today's fast-paced manufacturing world, especially in automotive and engineering sectors, businesses often encounter issues with off-the-shelf fasteners that fail to meet specific requirements, leading to inefficiencies and potential failures.

Revolutionizing Modern Manufacturing: OEM Fastener Customization

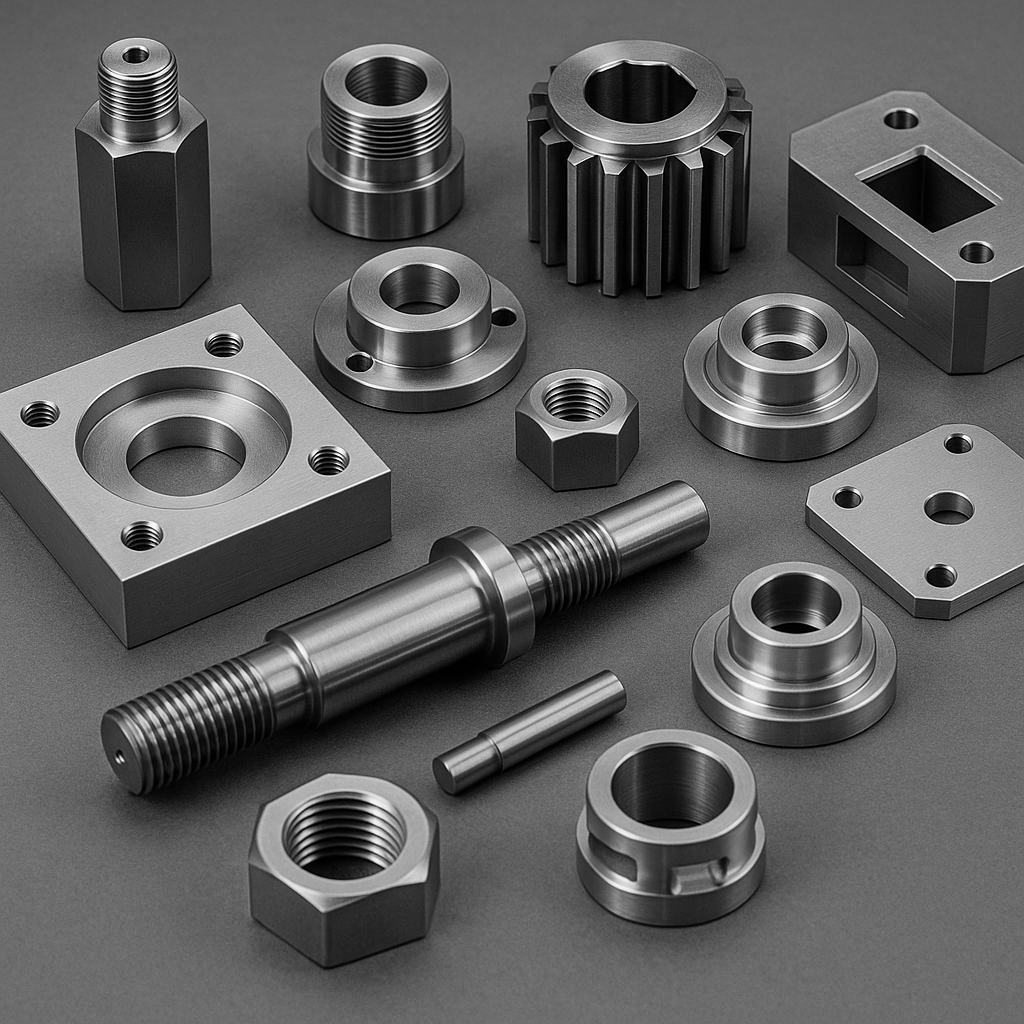

Precision at the Core of Industrial Assembly

Across modern manufacturing—from automotive and aerospace to heavy machinery—fasteners hold together not just parts, but entire systems of precision engineering. Standard off-the-shelf components often fail to meet the exact mechanical or environmental demands of advanced equipment. OEM fastener customization bridges this gap, enabling engineers to design parts that integrate seamlessly into specific structures and performance targets.

Engineering Design for Real-World Application

Customized fasteners are developed through engineering collaboration, where designers and manufacturers refine dimensions, materials, and coatings to match real-world conditions.

-

Dimensional tailoring ensures alignment with complex geometries.

-

Material optimization enhances tensile strength and fatigue resistance.

-

Surface treatments like galvanization or zinc-nickel plating protect against corrosion and wear.

-

Torque and load calibration ensures consistent performance under repeated stress.

This integration of mechanical design with production capability reduces assembly failure rates and simplifies downstream maintenance.

Technical Considerations for OEM Fastener Production

The effectiveness of customized fastening solutions lies in technical detail.

| Factor | Engineering Purpose | Manufacturing Advantage |

|---|---|---|

| Material Grade | Defines tensile, shear, and fatigue resistance | Matches mechanical properties to application |

| Thread Design | Controls torque transfer and vibration response | Improves assembly precision |

| Surface Coating | Enhances corrosion protection | Extends lifecycle and reduces maintenance |

| Tolerances | Ensures compatibility across assemblies | Improves installation speed |

OEM producers use CNC machining, cold heading, and thread rolling processes to achieve consistent accuracy, often verified through tensile testing, salt-spray tests, and metallographic inspection.

Applications in Modern Manufacturing

-

Automotive Engineering: high-torque bolts and lightweight alloys reduce vehicle weight while maintaining strength.

-

Renewable Energy Systems: stainless steel fasteners resist oxidation in wind turbine or solar array environments.

-

Construction Machinery: customized nuts and washers sustain repeated vibration and load cycles.

-

Aerospace Components: titanium fasteners offer high tensile strength and temperature resistance.

Each of these sectors relies on customized fastening systems to ensure both precision and durability in demanding environments.

Efficiency and Cost Optimization Through Customization

While customized production adds initial development cost, it reduces overall project expenditure through:

-

Reduced component failure rates.

-

Streamlined assembly processes.

-

Lower inventory requirements via standardization around tailored parts.

-

Improved field service reliability.

According to MarketsandMarkets, the global fastener market will surpass USD 125 billion by 2030, with OEM customization emerging as a primary growth driver.

Q&A: Technical Insights

Q1: What distinguishes OEM fastener production from standard manufacturing?

A: OEM production integrates engineering design, material science, and surface technology to match each client’s application, rather than relying on fixed catalog sizes.

Q2: How are mechanical properties verified?

A: Tensile, hardness, and fatigue testing ensure that each batch meets or exceeds international standards such as ISO 898 and ASTM F3125.

Q3: Can customized fasteners reduce production costs?

A: Yes. Through optimized geometry and targeted material use, OEM fasteners enhance performance while reducing waste and downtime.

Jingle’s Role in Advanced Fastener Manufacturing

With the shift toward intelligent and automated production, fasteners have evolved from passive components into engineered connectors. Jingle combines OEM customization, ISO-certified production, and global export expertise to deliver fastening systems that align with industrial innovation.

From precision bolts to complex assemblies, Jingle’s fastener solutions empower manufacturers to achieve higher reliability, efficiency, and product integrity in every build.

Learn more about our fastener customization services on the homepage or contact our engineering team through the contact page.