Understanding the Importance of the Lifting Clutch

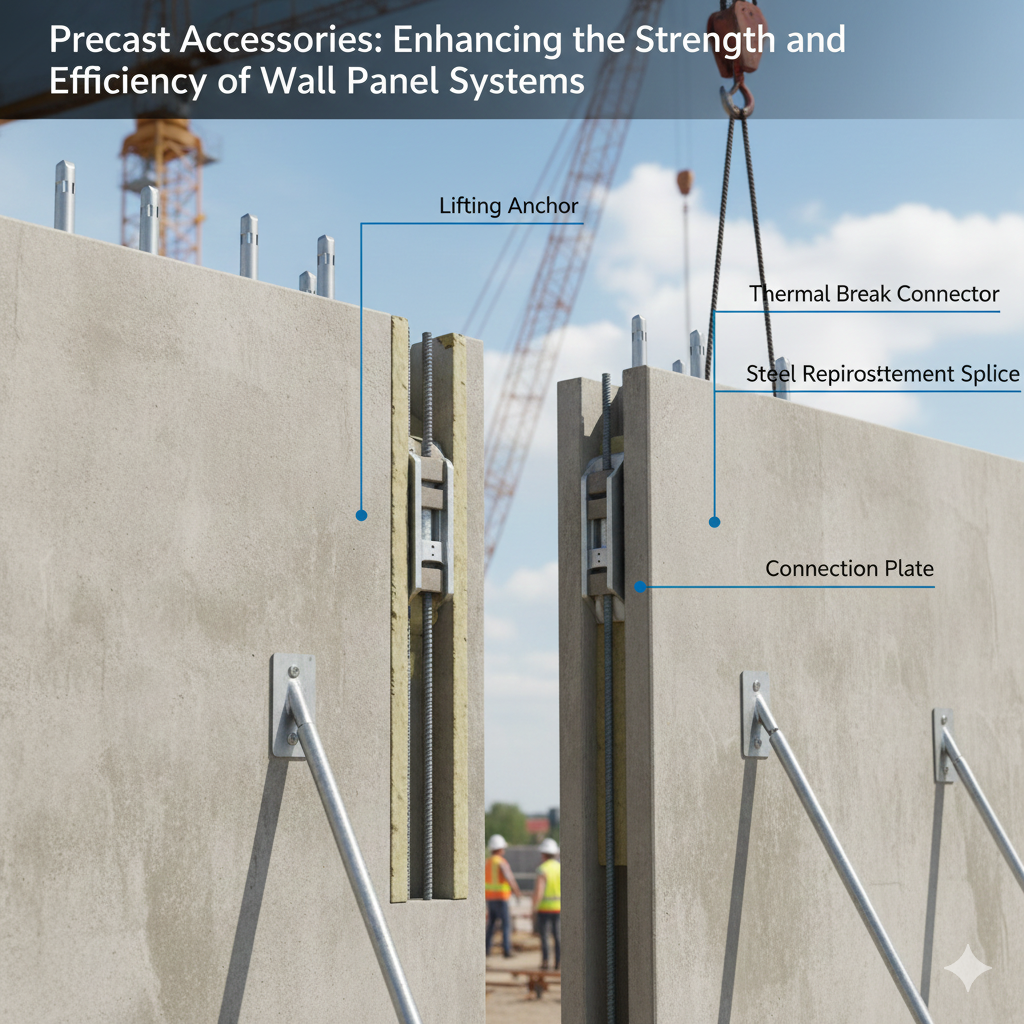

The lifting clutch is a fundamental component in the construction industry, particularly when dealing with heavy materials such as precast concrete. Designed to securely attach to lifting anchors, the lifting clutch enables safe and efficient handling of heavy precast elements during transport and installation. This essential tool is widely used in projects where precision and safety are of utmost importance.

How Lifting Clutches Work with Lifting Anchors

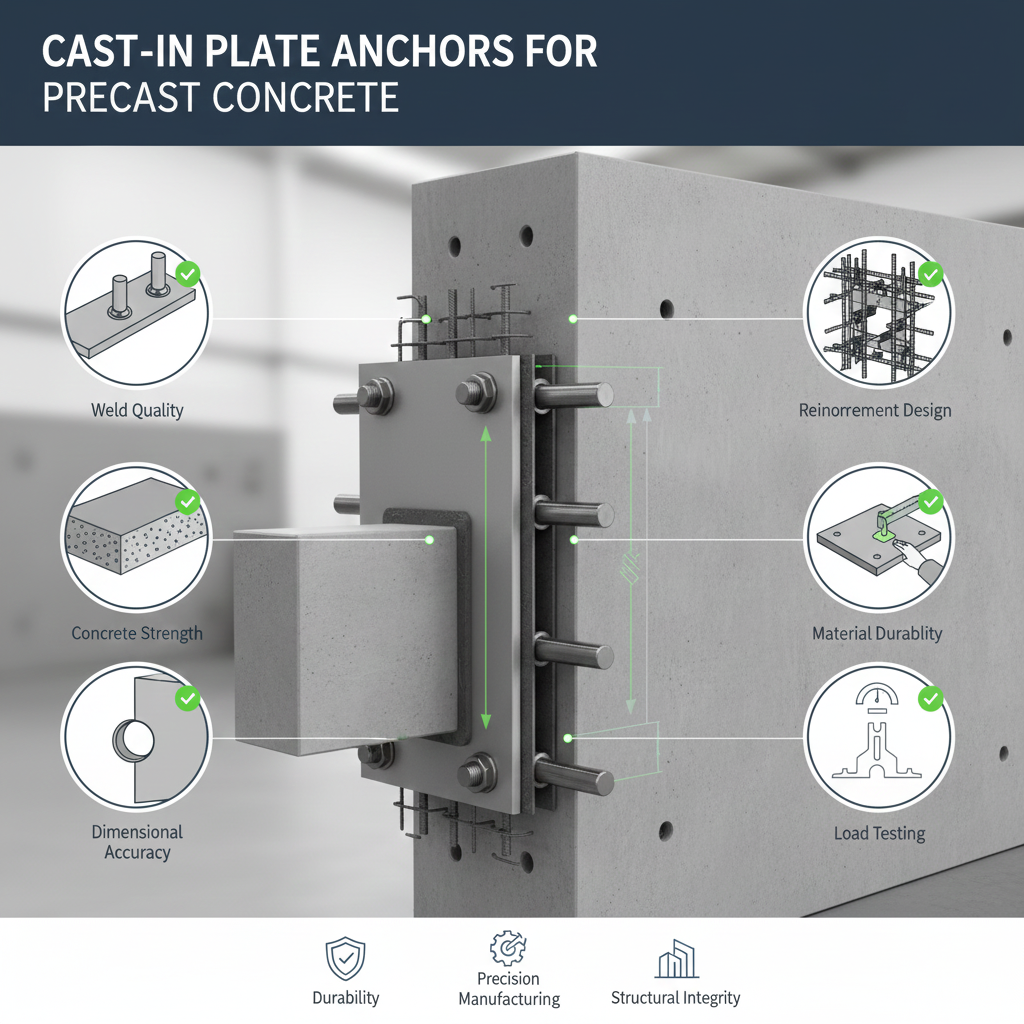

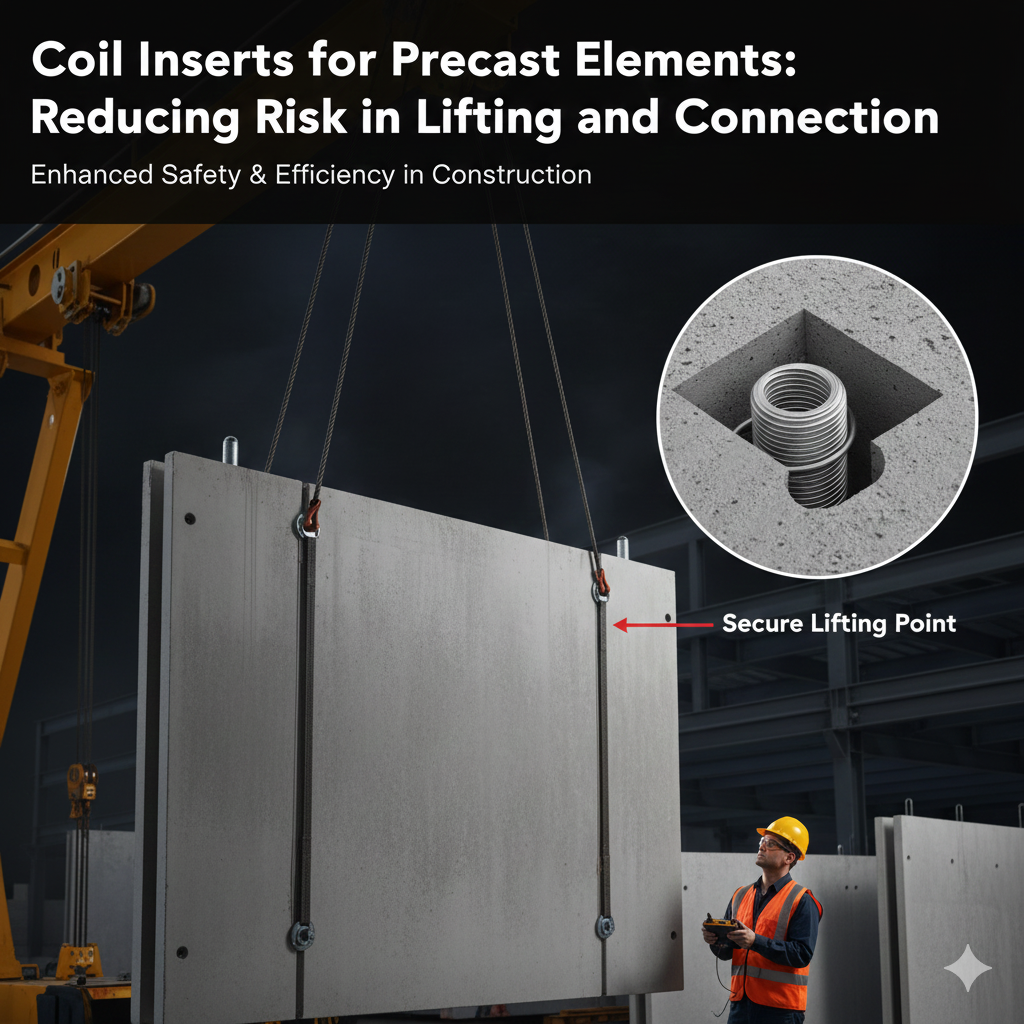

Lifting clutches are engineered to work seamlessly with lifting anchors, forming a reliable system for handling precast concrete units. The lifting anchor is embedded into the concrete during manufacturing, creating a secure joint for hoisting. The clutch is then attached to these anchors, ensuring a firm grip while moving heavy loads. This compatibility reduces risks such as slipping or rotation during lifting, making the process more efficient and safer for workers and machinery involved.

Applications in Precast Concrete Construction

In the construction sector, precast concrete has become a preferred choice for many architects and engineers due to its durability, efficiency, and versatility. Lifting clutches play a key role in this process by providing a secure mechanism for transporting and positioning concrete elements such as panels, beams, and slabs. With the use of lifting clutches, contractors can maintain high levels of precision during installation while minimizing accidents and operational downtime.

Benefits of Using Lifting Clutches

The advantages of opting for lifting clutches include enhanced safety for workers, reduced manual labor, and faster project completion times. Their compatibility with lifting anchors ensures a reliable hoisting system that can handle heavy loads with precision. Furthermore, the sturdiness of lifting clutches offers superior durability, making them an investment that pays off over time in any large-scale construction project.

Conclusion

In the modern construction environment, tools like the lifting clutch are indispensable for handling precast concrete elements effectively. By partnering with lifting anchors, they offer safety, efficiency, and precision, ensuring that complex construction projects can proceed smoothly. Whether you're dealing with small-scale operations or massive infrastructure projects, incorporating lifting clutches into your system can significantly enhance your workflow and reduce risks.