CNC Machined Hardware: Custom Solutions for Modern Furniture Manufacturing

The Demand for Custom Hardware in Modern Furniture

Furniture design has evolved over the years, with a growing emphasis on seamless aesthetics, innovative functionality, and durable materials. In today’s market, custom hardware is no longer a luxury—it's a necessity. Traditional hardware components, like visible screws and bolts, often interrupt the clean lines of modern furniture designs.

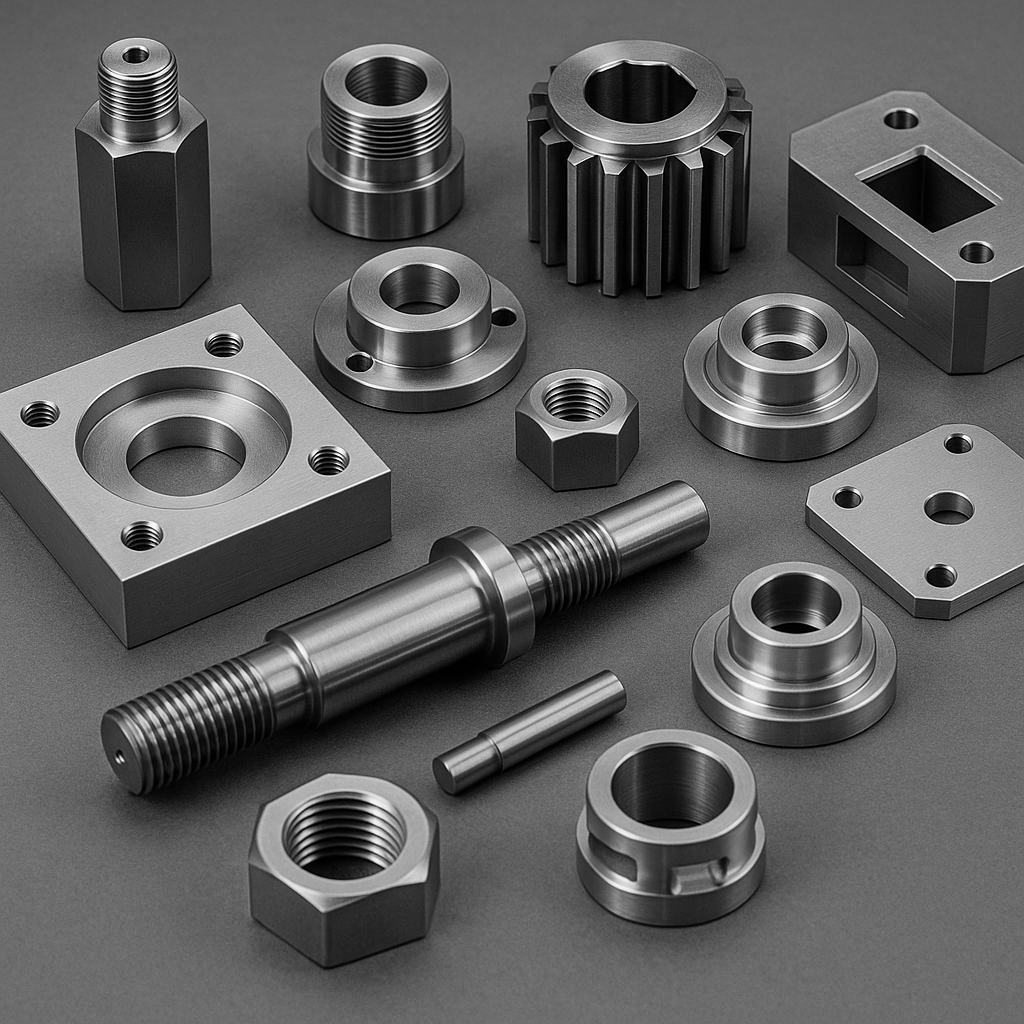

To meet the rising demand for sleek, functional furniture, CNC machining has become a key solution for custom hardware. From hidden fasteners that maintain a furniture piece's smooth surface to complex brackets and locks, CNC machining offers manufacturers the ability to create precise, tailored components that blend aesthetic integrity with structural strength.

How CNC Machining Enhances Furniture Manufacturing

CNC machining offers a unique combination of precision and flexibility, which makes it the ideal solution for furniture manufacturers looking to innovate. Here’s how CNC machining enhances modern furniture design:

-

Customized Components: CNC machining allows for the production of non-standard furniture parts such as custom brackets, hinges, handles, and fasteners, designed specifically for the unique needs of each project.

-

Seamless Integration: With CNC machining, furniture designers can create precise, invisible fasteners that don’t detract from the overall look and feel of the piece. Hidden fasteners, integrated seamlessly into the design, improve the aesthetics without compromising strength.

-

High-Precision: CNC machines are capable of producing components with micron-level precision, ensuring parts fit perfectly together and maintain structural integrity even in intricate designs.

-

Variety of Materials: CNC machining allows for the use of various materials, including stainless steel, aluminum, brass, and even wood composites, offering flexibility in design while maintaining strength, durability, and resistance to wear.

This combination of customization, precision, and aesthetic integration makes CNC machining the backbone of modern furniture hardware solutions.

JINGLE’s CNC Machining Solutions for Furniture Manufacturers

At JINGLE, we specialize in providing custom CNC machined hardware solutions for furniture manufacturers looking for tailored components that meet both functional and aesthetic requirements.

-

OEM Customization: We work directly with furniture designers and manufacturers to create custom components that fit their specific design needs, whether it’s a unique hinge, a custom fastener, or a specialized bracket.

-

Certified Quality: JINGLE ensures that all components are manufactured to the highest ISO standards, offering certified parts that meet global quality requirements for durability and reliability.

-

End-to-End Solutions: From concept and prototyping to mass production, JINGLE’s factory provides full-scale support, ensuring that each component maintains consistent quality across large orders.

-

Material Expertise: We offer expertise in machining a wide range of materials, ensuring that the parts are not only functional but also suited for the desired aesthetic, whether the project requires high-strength steel or lightweight aluminum.

-

Fast Turnaround: With our state-of-the-art CNC machines and ERP-driven production systems, we guarantee fast production times, allowing furniture manufacturers to meet tight deadlines without compromising quality.

Applications of CNC Machined Hardware in Furniture

CNC machining has wide applications across modern furniture manufacturing, including:

-

Custom Fasteners: These fasteners allow for invisible integration into the furniture, ensuring strength and durability while maintaining aesthetic appeal.

-

Brackets and Housings: Custom brackets and reinforced housings are produced with precise CNC machining to ensure durability and easy installation in modular furniture systems.

-

Furniture Accessories: Handles, locks, and other furniture accessories can be tailored to match the furniture design while offering smooth functionality.

-

Structural Components: CNC-machined components are used in supporting structures like cabinet frames, bed frames, and tables where strength and precision are essential.

By utilizing CNC machining for furniture hardware, designers can push the boundaries of what’s possible, creating custom furniture that is both beautiful and functional.

The Future of CNC Machined Furniture Hardware

As the demand for sustainable, minimalist furniture continues to grow, CNC machining will remain at the heart of furniture manufacturing innovations. With advancements in materials and machining technologies, CNC-machined hardware will continue to evolve to meet design trends while enhancing functionality.

JINGLE’s expertise in custom CNC machining provides furniture manufacturers with the tools they need to bring creative, high-quality furniture designs to life, offering precision, durability, and aesthetic integration.

Discover more about JINGLE’s CNC machining solutions for furniture manufacturers on the official website or connect via the contact page.