Choosing the Right Fastener Manufacturer for Global Projects

Why Fastener Quality Defines Project Success

For contractors, importers, and distributors, the fastener manufacturer you choose directly impacts safety, reliability, and project timelines. A single weak bolt in a bridge, machinery, or automotive assembly can lead to costly failures. This is why sourcing from a certified fastener manufacturer is not just about price—it is about ensuring compliance, performance, and long-term trust. Fasteners may look simple, but in reality, they carry the structural integrity of entire projects.

Key Standards Every Importer Should Check

When evaluating suppliers, buyers should look for internationally recognized certifications such as ISO 9001 and ISO/TS 16949. The International Organization for Standardization (ISO) sets these benchmarks to ensure consistent quality management across industries. Beyond paperwork, professional buyers also request tensile strength, hardness, and corrosion-resistance test reports aligned with standards from ASTM International, which defines specifications for metals, coatings, and testing procedures.

Fastener manufacturers who comply with these standards can provide full traceability—from raw materials to finished products. This is particularly critical for government infrastructure projects or automotive supply chains, where documentation and compliance are mandatory.

The Risks of Working with Unverified Suppliers

Sourcing from unverified or low-cost suppliers might appear economical in the short term, but it often results in hidden costs. Delayed shipments, inconsistent quality, or even project failures can multiply expenses. According to the Industrial Fasteners Institute (IFI), inadequate fasteners are a leading cause of unexpected downtime in industrial machinery. Contractors face potential liability claims, while importers may lose credibility if products fail to meet safety standards.

Another overlooked risk is counterfeit certification. Some small factories issue certificates without real testing. Importers should always request authentic reports and, if possible, third-party verification. Working with a trusted manufacturer helps buyers avoid these pitfalls and ensures smooth supply chain operations.

Why Jingle Stands Out as a Trusted Manufacturer

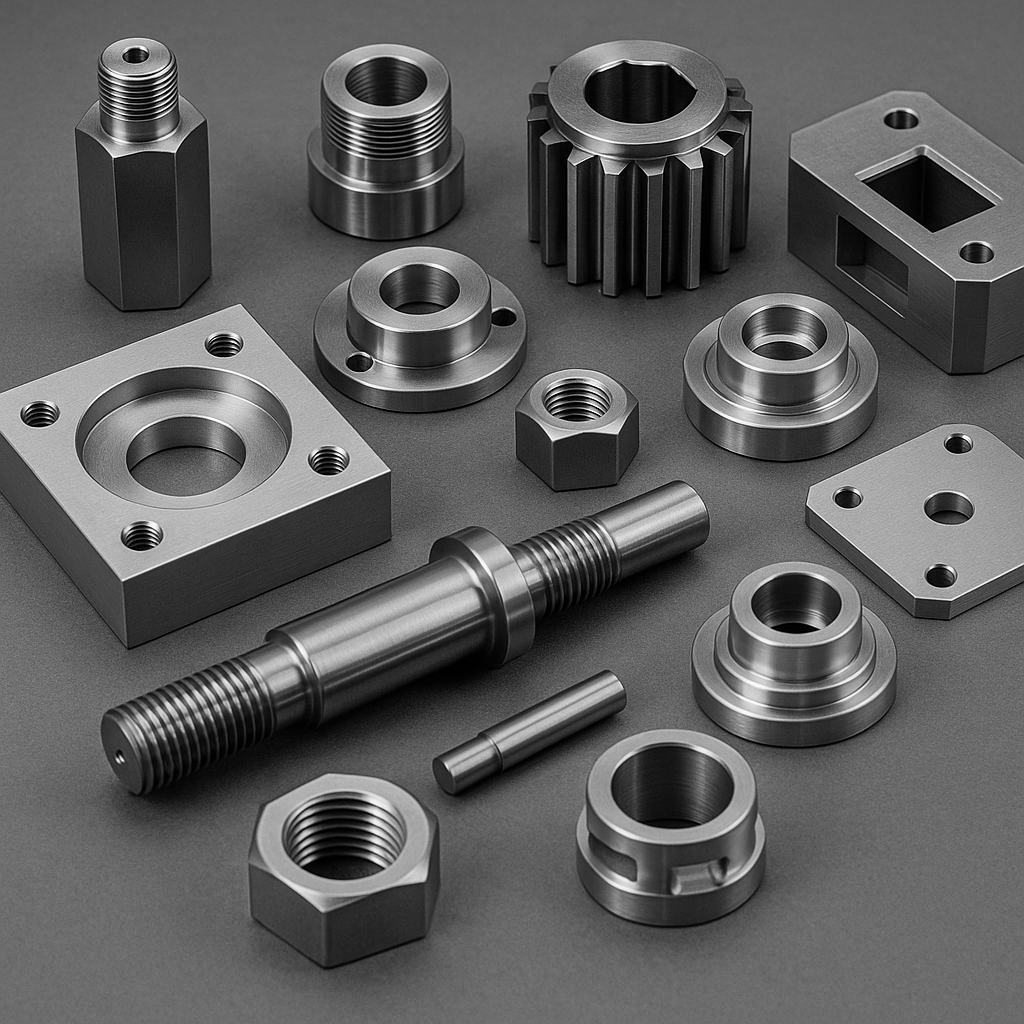

With over two decades of experience, Jingle has built a reputation as a reliable fastener manufacturer serving construction, automotive, and industrial sectors. Our factory is equipped with over 100 CNC machines and multiple automated production lines, supported by SAP ERP for production traceability. We provide OEM/ODM solutions, customized packaging, and flexible logistics to match the needs of global importers and contractors.

Quality is at the core of our operation. Every batch undergoes strict in-house testing, covering tensile strength, salt-spray corrosion resistance, and dimensional accuracy. By combining advanced machining and automated quality control, Jingle ensures both consistency and scalability for large-volume projects.

Application Scenarios Across Industries

-

Construction Projects: High-strength bolts, anchor bolts, and threaded rods used in bridges, tunnels, and high-rise buildings.

-

Automotive Industry: Precision nuts and bolts designed for engine assemblies, safety systems, and chassis components.

-

Machinery Manufacturing: Custom CNC parts and fastening systems for heavy equipment, minimizing downtime and maximizing durability.

-

Precast Engineering: Accessories and fastening solutions designed for concrete structures, ensuring secure and efficient installation.

These scenarios highlight how different industries prioritize different features: corrosion resistance for marine projects, heat resistance for automotive engines, or precision tolerances for machinery.

What Buyers Should Expect in a Reliable Supplier

When importers or contractors evaluate a fastener manufacturer, several factors matter beyond price:

-

Production Capacity: Ability to handle both bulk orders and custom small batches.

-

Technical Support: Engineering teams that can help optimize designs and reduce costs.

-

Global Logistics: Experience in managing shipping, customs, and on-time delivery worldwide.

-

Sustainability: Increasingly, large buyers require eco-friendly production and ISO 14001 compliance.

Suppliers who combine these strengths are better positioned to support long-term partnerships.

Cost Control and Supply Chain Efficiency

Choosing the right manufacturer is also about controlling total cost of ownership. While initial unit prices matter, importers save more when a supplier ensures fewer defects, lower rejection rates, and faster assembly times. Some manufacturers also offer Vendor Managed Inventory (VMI) or flexible stocking arrangements, which help distributors reduce warehousing costs. For large-scale contractors, direct factory supply reduces the reliance on middlemen and improves margin stability.

Future Trends in the Fastener Industry

The global fastener market is evolving rapidly. Demand for stainless steel and high-performance alloys is growing, especially in renewable energy projects and EV manufacturing. Digitalization is also reshaping the sector, with ERP-integrated production and automated testing ensuring real-time traceability. Manufacturers investing in smart factories and sustainability initiatives will stand out as preferred partners in the coming decade.

Partnering with the Right Manufacturer for Long-Term Growth

Fasteners are not just small components—they are the backbone of every project. By working with a certified manufacturer, importers and contractors reduce risks, improve cost efficiency, and secure long-term reliability. Whether for infrastructure, machinery, or automotive projects, choosing the right partner can mean the difference between costly delays and successful project completion.

Looking for a reliable fastener manufacturer? Contact Jingle today to explore OEM/ODM solutions and ensure your projects are built on trusted quality.