Industrial hardware plays a crucial role in construction, mechanics, and engineering, ensuring that projects are executed with durability, precision, and efficiency. An essential component in this realm is the lifting anchor, a versatile solution designed to bear significant loads while maintaining reliability in even the most demanding environments.

The Problem: Stability and Reliability in Heavy-Duty Applications

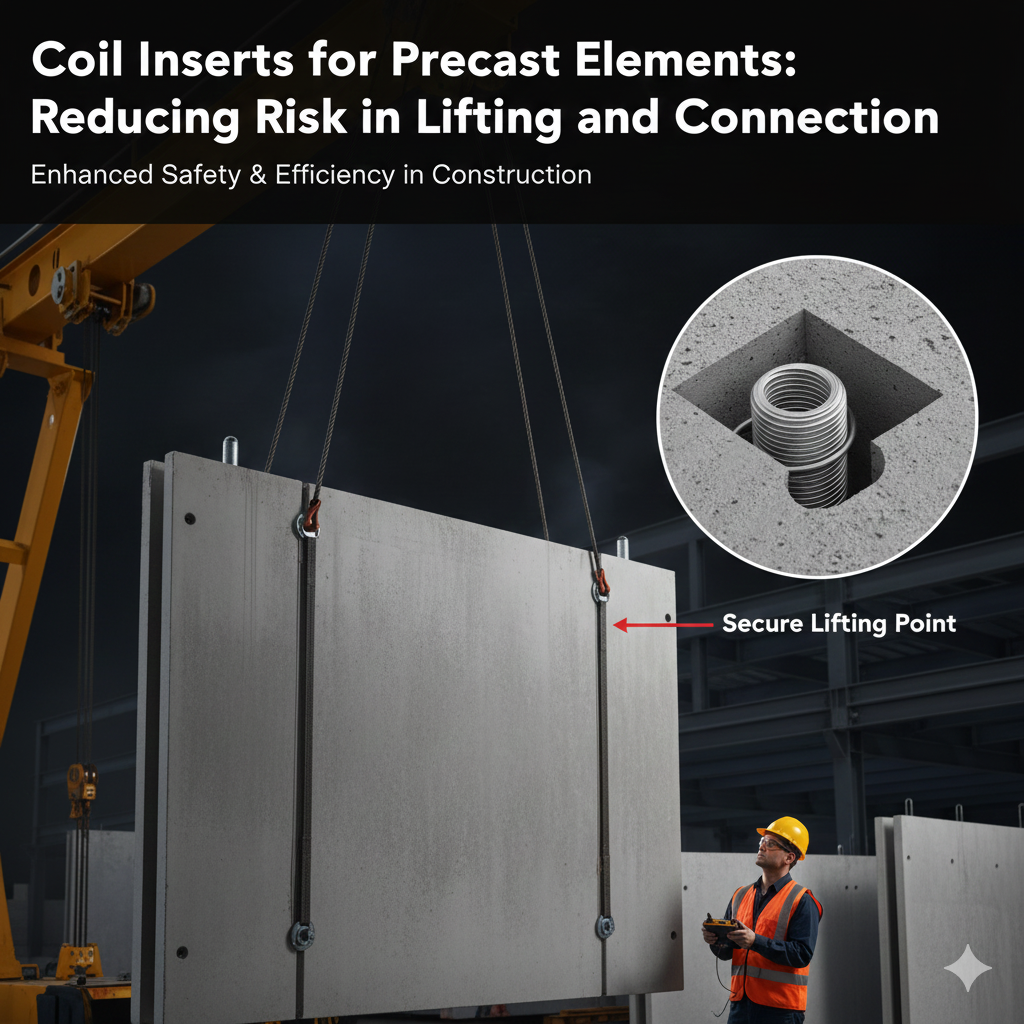

When it comes to heavy-duty operations, whether in construction, machinery assembly, or maritime setups, ensuring stability and load-bearing reliability is a primary concern. Without the right hardware, projects can suffer from inefficiency, delays, or even structural failures. Tasks like lifting and anchoring equipment demand specialized solutions that can withstand substantial tension and weight while maintaining long-term performance. Additionally, exposure to harsh environments such as moisture, salt, and heavy wear and tear amplify the need for durable solutions.

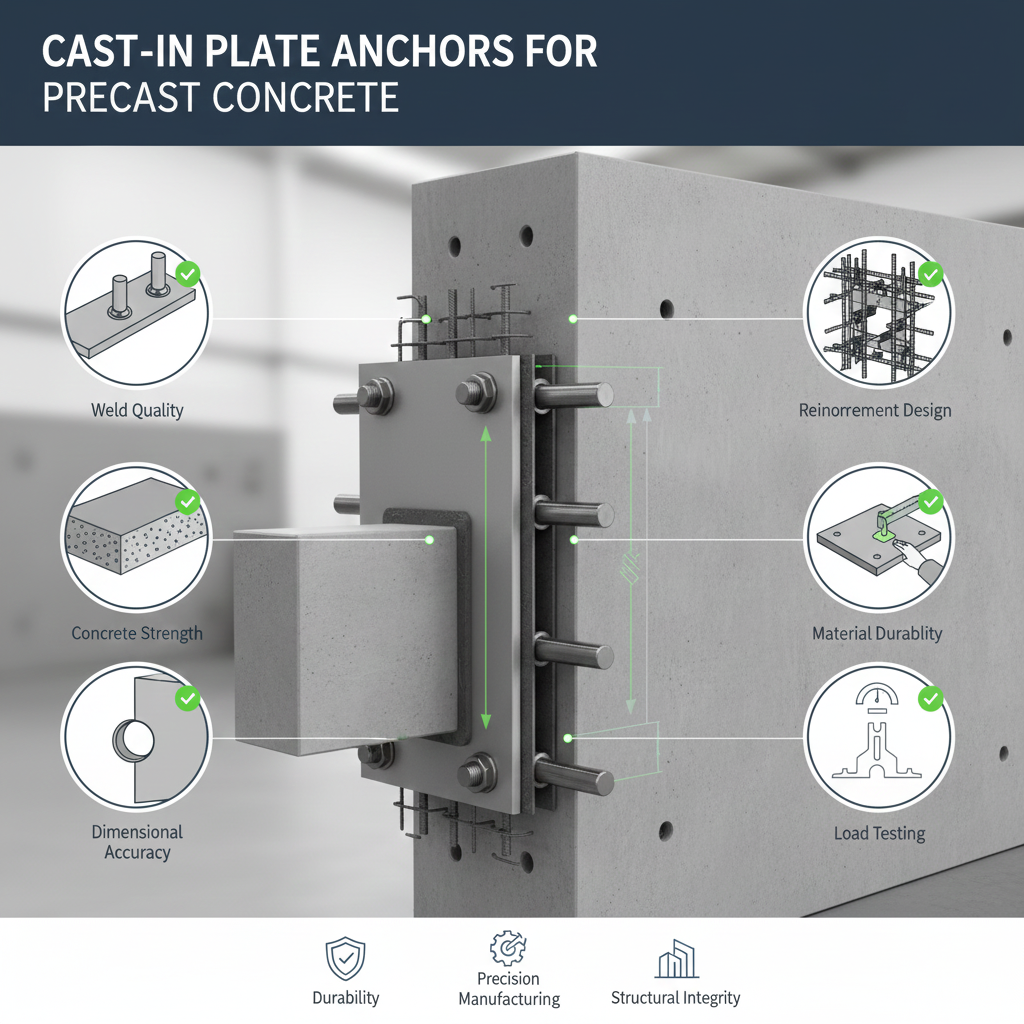

The Solution: Harnessing the Power of Lifting Anchors and Accessories

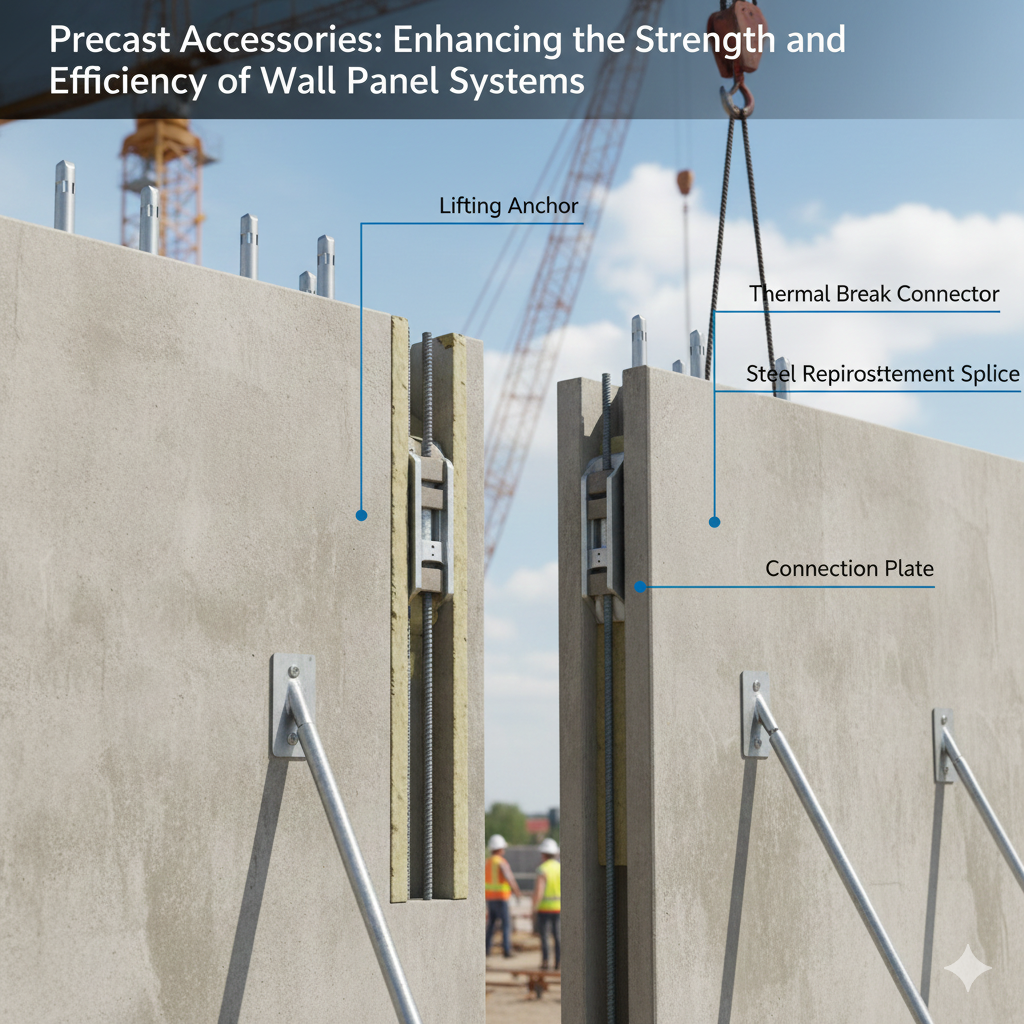

At the heart of the solution lies the robust lifting anchor, a carefully crafted component designed to provide essential stability and strength in industrial applications. These anchors are engineered with high-grade materials, ensuring they deliver uncompromising performance even under substantial strain. When paired with the right supporting hardware, such as **eye bolts** and **hook anchors**, the lifting anchor becomes an indispensable asset for lifting, securing, and anchoring equipment with confidence.

Industrial Hardware Designed for Modern Challenges

What makes these components exceptional is their adaptability and durability. The lifting anchors and supporting hardware come in various finishes to address diverse needs. Galvanized options are particularly effective in environments prone to corrosion, offering long-term resilience against moisture and rust. Sleek black-coated alternatives deliver an industrial-modern look while still excelling in utility. For those seeking customization, raw metal finishes provide a blank canvas to cater to specific design requirements.

Why Choose These Solutions?

This ensemble of industrial hardware represents the perfect blend of raw power and refined craftsmanship. Each piece is a testament to the importance of quality engineering, delivering not only functionality but also style. When durability is non-negotiable and precision is paramount, these components rise to the occasion, ensuring that projects are executed flawlessly whether in construction sites, mechanical workshops, or offshore platforms.

In conclusion, lifting anchors and their supporting hardware are the unsung heroes that make the infrastructure and innovations of today possible. By addressing the challenges of stability, durability, and versatility, these tools are indispensable in creating structures that stand the test of time. Whether for massive industrial applications or precision-driven tasks, their strength and reliability provide the foundation upon which the future is built.