Understanding the Significance of a Lifting Clutch

A lifting clutch is a crucial component in industrial lifting applications, providing the necessary support and effectiveness in handling heavy loads. Especially in manufacturing and construction industries, where safety and reliability are paramount, the lifting clutch plays a key role in ensuring smooth operations. From assembling machinery to hoisting materials, these devices are designed to withstand the rigors of demanding environments.

Lifting clutches are often paired with advanced equipment such as swivel hoist rings to optimize performance. These clutches serve as the intermediary mechanism to secure loads, ensuring precision and stability during the lifting process. Given the high importance of load security, manufacturers continue to invest in innovative designs that offer unparalleled reliability and safety.

Features of Swivel Hoist Rings That Enhance Lifting Performance

Among contemporary lifting solutions, the Swivel Hoist Rings stand out as an indispensable tool in industrial-grade lifting tasks. Crafted from high-strength steel with a corrosion-resistant coating, these rings are built to endure challenging environments and offer superior longevity. Their golden finish not only provides aesthetic appeal but also serves as a protective measure against wear and environmental factors.

One of the most impressive features of swivel hoist rings is the 360-degree rotation mechanism. This ensures smooth maneuverability, even with uneven or complex loads. The ability to rotate freely reduces the risk of instability, making these hoist rings reliable for lifting applications that involve motion or adjusting angles. Paired with their long-threaded bolt design, they offer a firm and secure attachment to mounting surfaces, further boosting load-handling confidence.

Available in various sizes, these swivel hoist rings cater to different load capacities, making them highly adaptable across diverse industries. Whether in manufacturing assembly lines or construction sites, their ergonomic design ensures easy installation and usability, making them a preferred choice for professionals seeking efficiency and reliability during lifting operations.

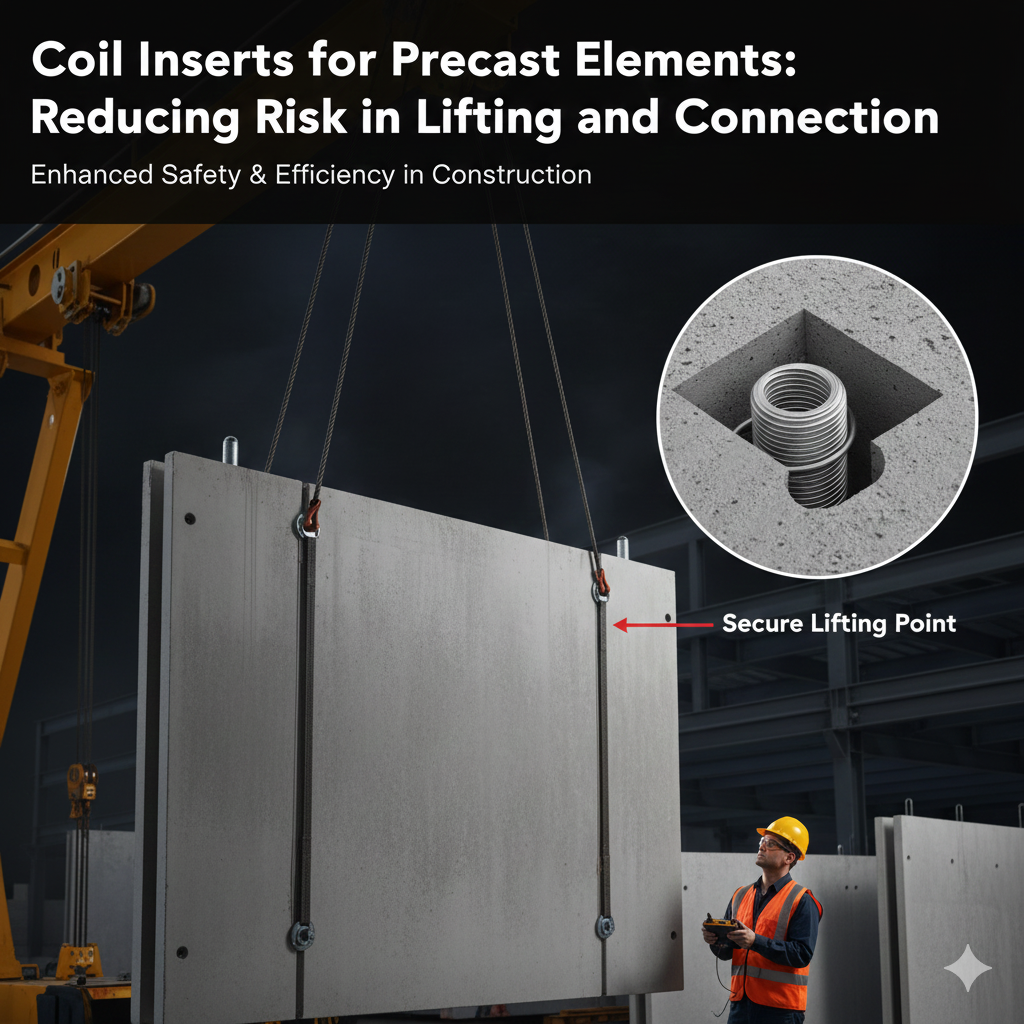

Applications and Benefits in High-Stake Industries

Swivel hoist rings equipped with lifting clutches are particularly useful in industries where the stakes are high. Manufacturing facilities frequently utilize these tools for precisely positioning heavy machinery, while construction sites depend on their strength for hoisting materials and equipment safely. The flexibility and reliability offered by these rings allow workers to focus more on the execution of tasks and less on concerns regarding equipment failure or instability.

Another key advantage is their adaptability. The ergonomic and versatile design makes swivel hoist rings suitable for various setups requiring flexibility. This adaptability minimizes downtime during installations and adjustments, ensuring that operations proceed smoothly. Furthermore, the corrosion-resistant coating and robust build provide extended durability, saving costs on replacements and maintenance in the long term.

Engineered with precision and reinforced with advanced safety features, the swivel hoist rings redefine efficiency for businesses. Their ability to blend performance with modern aesthetics makes them a valuable addition to the arsenal of professionals working on demanding lifting applications. When paired with lifting clutches, they ensure heavy loads are handled securely and efficiently every time.

By integrating innovative engineering and durable components, the Swivel Hoist Rings are not just tools but dependable companions in the quest for operational excellence in high-stake environments.