Micro Fasteners in IoT Devices: Ensuring Compact Reliability

Understanding the Challenges of Miniaturized IoT Devices

IoT devices are shrinking rapidly while their functionality continues to expand. Wearables, smart home devices, industrial sensors, and 5G modules require tight assembly spaces where every component must fit precisely.

In such miniaturized environments, standard fasteners are often too large or inconsistent, potentially causing misalignment, stress points, or assembly difficulties. Micro fasteners address these challenges by providing structural support and enabling compact, reliable device architectures.

Devices such as smart sensors or wearable health monitors must maintain long-term durability despite exposure to environmental factors, vibration, and frequent handling. High-quality micro fasteners are crucial to meet these demands without increasing device size or compromising design integrity.

Precision Engineering Behind Reliable Fasteners

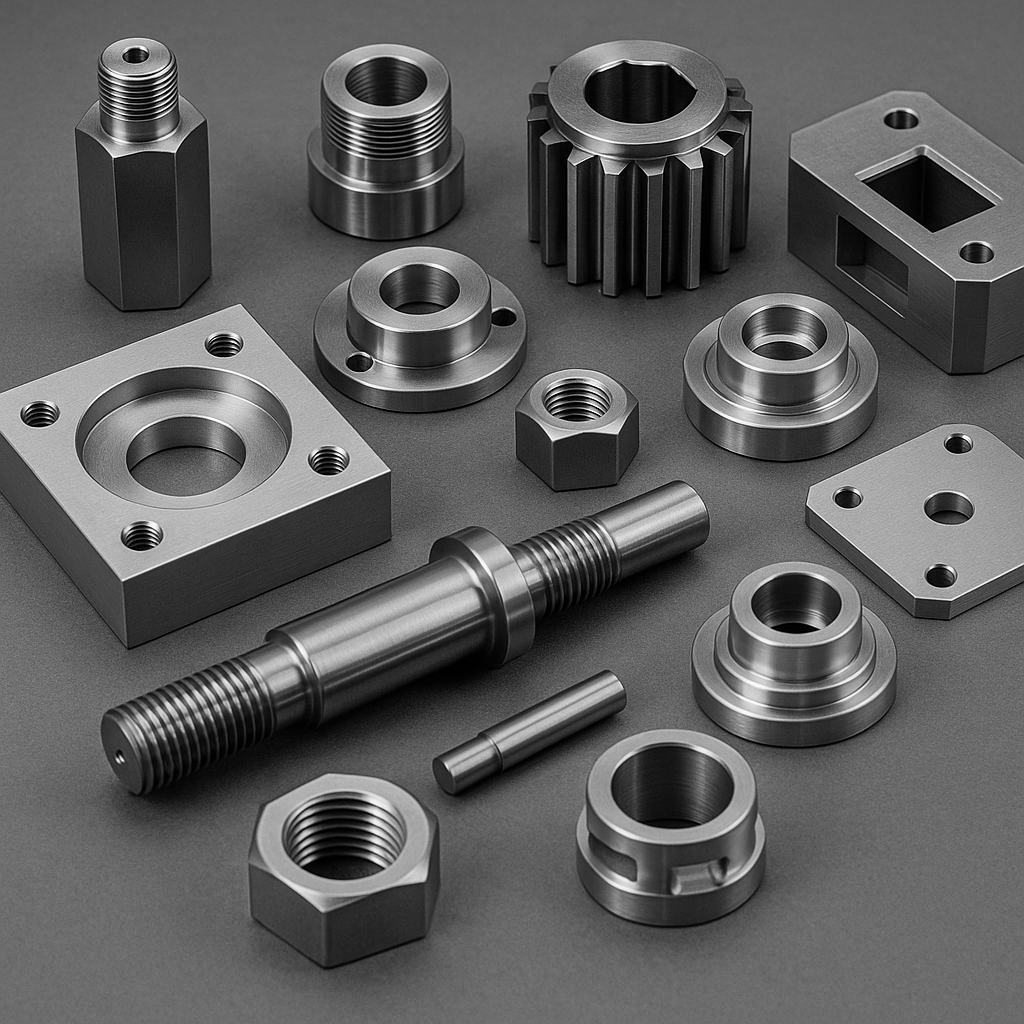

The performance of IoT devices depends heavily on the engineering quality of micro fasteners. CNC machining is central to achieving the micron-level tolerances necessary for these components:

-

Exact Dimensions: CNC machining ensures each fastener fits perfectly within dense electronic assemblies.

-

Material Versatility: Micro fasteners are made from stainless steel, titanium, or lightweight aluminum alloys, balancing strength, weight, and corrosion resistance.

-

Custom Geometry: Threads, lengths, and head designs are tailored to each device, ensuring functional and aesthetic alignment.

-

Surface Finishing: Smooth, treated surfaces reduce wear and enhance compatibility with sensitive electronics.

-

Batch Consistency: CNC processes deliver identical components across prototypes and production runs, essential for OEM reliability.

Through these practices, micro fasteners provide both mechanical integrity and space-saving assembly solutions, enabling device miniaturization without sacrificing performance.

Tailored Solutions from JINGLE for High-Performance Assemblies

JINGLE specializes in OEM micro fastener solutions, supporting manufacturers in producing compact, reliable IoT devices. Key advantages include:

-

Custom OEM Design: Fasteners are designed to fit unique device architectures, including wearables, 5G modules, and robotics assemblies.

-

Certified Manufacturing: ISO and CE-certified processes ensure global compliance and high-quality standards.

-

High-Volume Scalability: CNC machining enables consistent precision from small prototype batches to large-scale production.

-

Material Expertise: Lightweight, high-strength, and corrosion-resistant materials optimize device reliability.

-

Rapid Turnaround: Streamlined CNC production supports fast prototyping and timely market delivery.

These capabilities allow manufacturers to reduce assembly risks, maintain compact form factors, and achieve highly reliable IoT devices at scale.

Real-World Applications in IoT, Robotics, and 5G

Micro fasteners are integral to multiple sectors:

-

Wearable Devices: Fitness trackers, smartwatches, and medical monitors rely on micro fasteners for ergonomic, compact casings.

-

Smart Home Devices: Sensors, hubs, and smart meters utilize precision fasteners to secure delicate electronic components.

-

Industrial Robotics: Micro fasteners support motion-critical joints, sensor housings, and modular assemblies, ensuring reliability under high-vibration conditions.

-

5G Communication Equipment: Micro fasteners enable high-density PCB assemblies and precise alignment of RF modules, critical for network performance.

In each scenario, these components enhance structural integrity, assembly accuracy, and device longevity, demonstrating their vital role in next-generation electronic systems.

Addressing Common Assembly and Reliability Concerns

Q1: Are micro fasteners difficult to install in small devices?

A: Not with properly engineered designs. JINGLE fasteners are compatible with automated assembly and manual processes, even in high-density layouts.

Q2: Can micro fasteners withstand industrial IoT conditions?

A: Yes. Material selection and CNC precision ensure fasteners remain durable under vibration, heat, and stress.

Q3: Does CNC machining improve consistency for mass production?

A: Absolutely. CNC processes guarantee tight tolerances, smooth finishes, and identical components, critical for OEM scalability.

Q4: Are these fasteners suitable for 5G electronics?

A: Yes. Micro fasteners support compact, high-frequency electronics while maintaining mechanical stability and precision alignment.

Why High-Quality Micro Fasteners Matter

High-quality micro fasteners are more than small components—they enable:

-

Compact Device Design: Maximize space efficiency in dense assemblies.

-

Reliable Performance: Ensure long-term operation under challenging conditions.

-

OEM Flexibility: Support tailored designs and scalable production.

-

Reduced Product Failure: Prevent misalignment, stress, and component loosening.

JINGLE provides precision-engineered micro fasteners that meet these needs, allowing manufacturers to innovate in compact, high-performance IoT devices.

Discover JINGLE’s micro fasteners for IoT, robotics, and 5G applications on the official website or explore custom solutions via the contact page.