Introduction to Precast Lifting Clutch

Precast lifting clutches play a vital role in modern construction, particularly when it comes to lifting and handling precast concrete components. Designed to ensure safe and efficient lifting procedures, precast lifting clutches provide a reliable solution for maneuvering heavy materials, which reduces operational risks on-site. Incorporating advanced engineering concepts, they are indispensable for maintaining safety standards in construction projects involving precast elements.

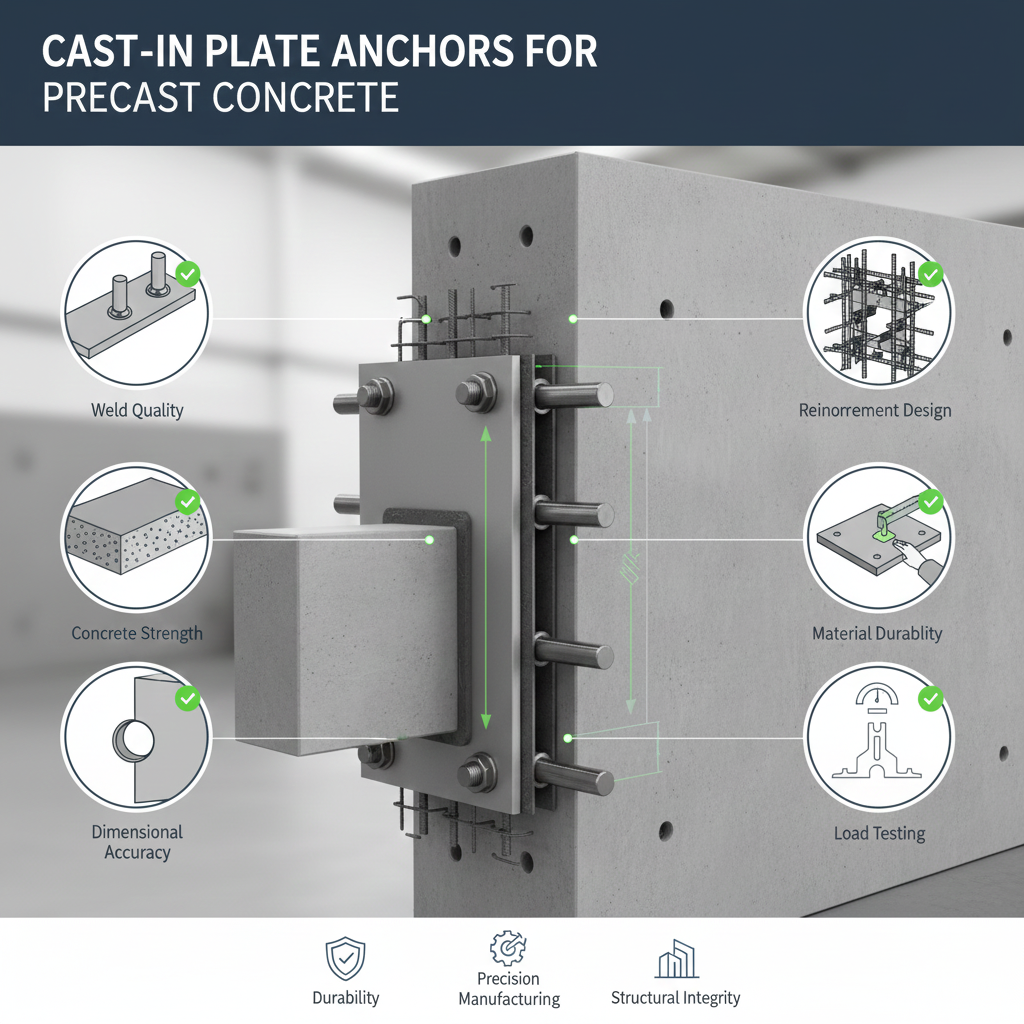

Main Features and Benefits

Precast lifting clutches are ergonomically designed to cater to the unique requirements of handling precast concrete components. Some prominent features of precast concrete lifting clutches include their high load-bearing capacity, robust construction, and ease of attachment and detachment to precast elements. These tools are crafted from high-quality materials, ensuring durability and resistance to wear-and-tear in heavy-duty applications.

One of the significant advantages of these clutches is their versatility. They can be used with different lifting systems, providing construction teams with flexibility. Furthermore, their reliable locking mechanisms prevent accidental disengagement, which enhances on-site safety and efficiency during handling and lifting operations.

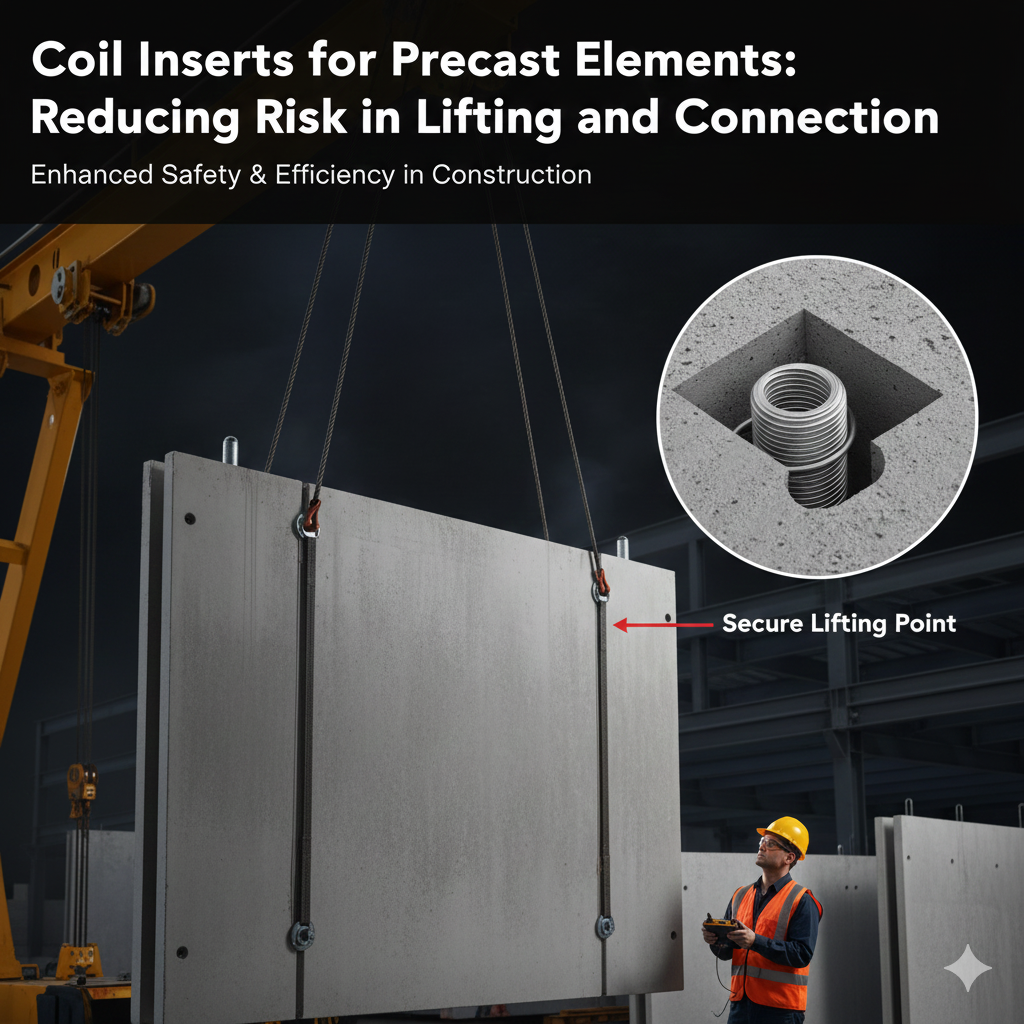

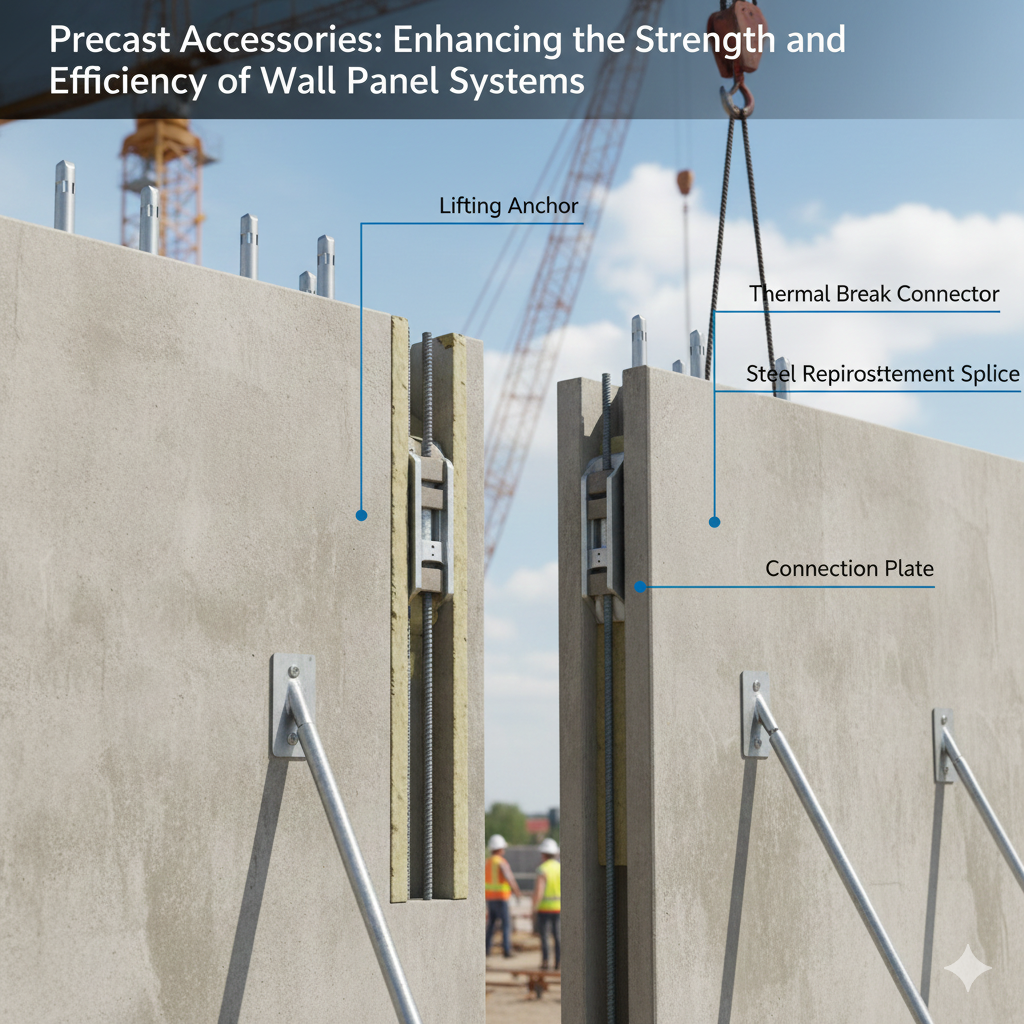

Applications in Modern Construction Projects

Precast lifting clutches are instrumental in a variety of applications in modern construction projects. From bridges and tunnels to residential buildings and industrial facilities, precast concrete lifting clutches are frequently utilized to lift precast beams, panels, and slabs. Their precision in operation ensures that heavy concrete components are lifted and positioned accurately, facilitating faster construction processes and reducing the cost and time implications.

Additionally, these clutches help meet strict safety and quality assurance standards required in construction. Engineers and builders rely on their effectiveness to make installations smoother, avoiding potential hazards or delays that may arise when dealing with large and cumbersome precast materials.

Conclusion

In summary, precast lifting clutches are indispensable tools in the construction industry, especially for projects involving precast concrete components. Their ability to deliver safety, efficiency, and precision makes them a preferred choice for builders worldwide. By investing in high-quality precast concrete lifting clutches, construction companies can enhance project workflows while maintaining adherence to stringent safety protocols.