Understanding the Core: What is a Pin Anchor?

In the realm of construction and material handling, particularly with precast concrete elements, the efficiency and safety of lifting and anchoring systems are paramount. A fundamental component in many such systems is the pin anchor. This type of anchor is designed to be embedded within a concrete structure, providing a secure and reliable point for lifting, transporting, or fixing elements. The pin anchor typically features a specially shaped head that allows for the connection of a lifting device, ensuring that heavy loads can be managed with confidence. Its robust design is crucial for withstanding the stresses involved in moving and placing large concrete sections, making it an indispensable part of modern construction methodologies.

Exploring Anchor Varieties: The Role of the Eye Anchor

While the pin anchor serves as a primary solution, the broader family of anchoring devices includes various designs tailored for specific needs. One such related component often discussed in conjunction with lifting systems is the eye anchor. An eye anchor, as its name suggests, typically features a looped end or an 'eye' which provides a versatile connection point. In some systems, an eye anchor might be used in situations where a different type of lifting clutch or attachment mechanism is preferred, or it can be part of a more complex assembly. The design of an eye anchor, like the pin anchor, is focused on creating a strong, reliable void or connection within the concrete that can effectively transfer loads to a lifting device, ensuring the integrity of the element during handling.

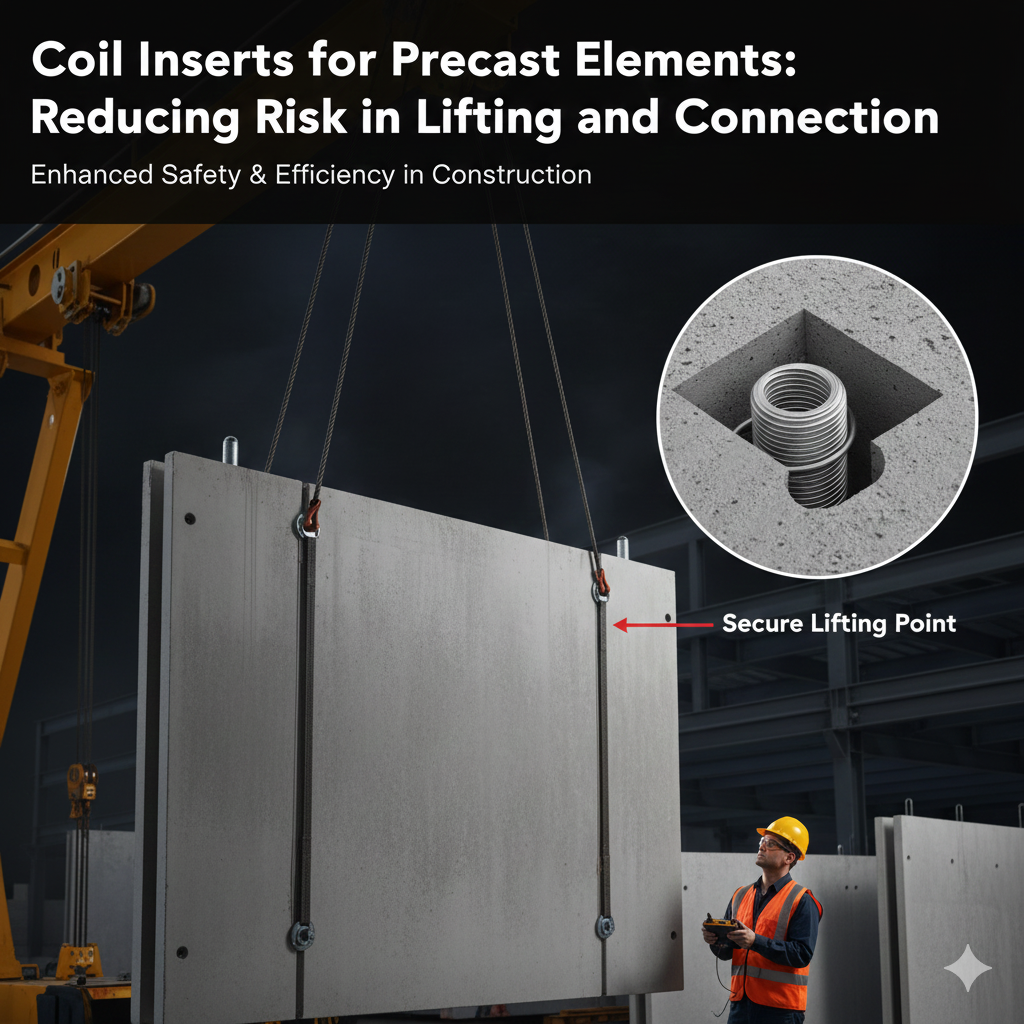

The Lifting Mechanism: Introducing the Ring Clutch

To effectively utilize embedded anchors like the pin anchor or similar designs, a specialized lifting device is required. This is where the ring clutch comes into play. A ring clutch is a mechanical lifting device specifically designed to engage with the head of the anchor embedded in the concrete. It typically features a locking mechanism that securely grips the anchor head, allowing for the safe lifting and maneuvering of the concrete element. The design of the ring clutch is critical; it must provide a strong and positive connection that can be easily engaged and disengaged by operatives, yet remain secure under load. The synergy between the anchor and the ring clutch is what enables the efficient and safe handling of heavy precast components, from factory to final installation.

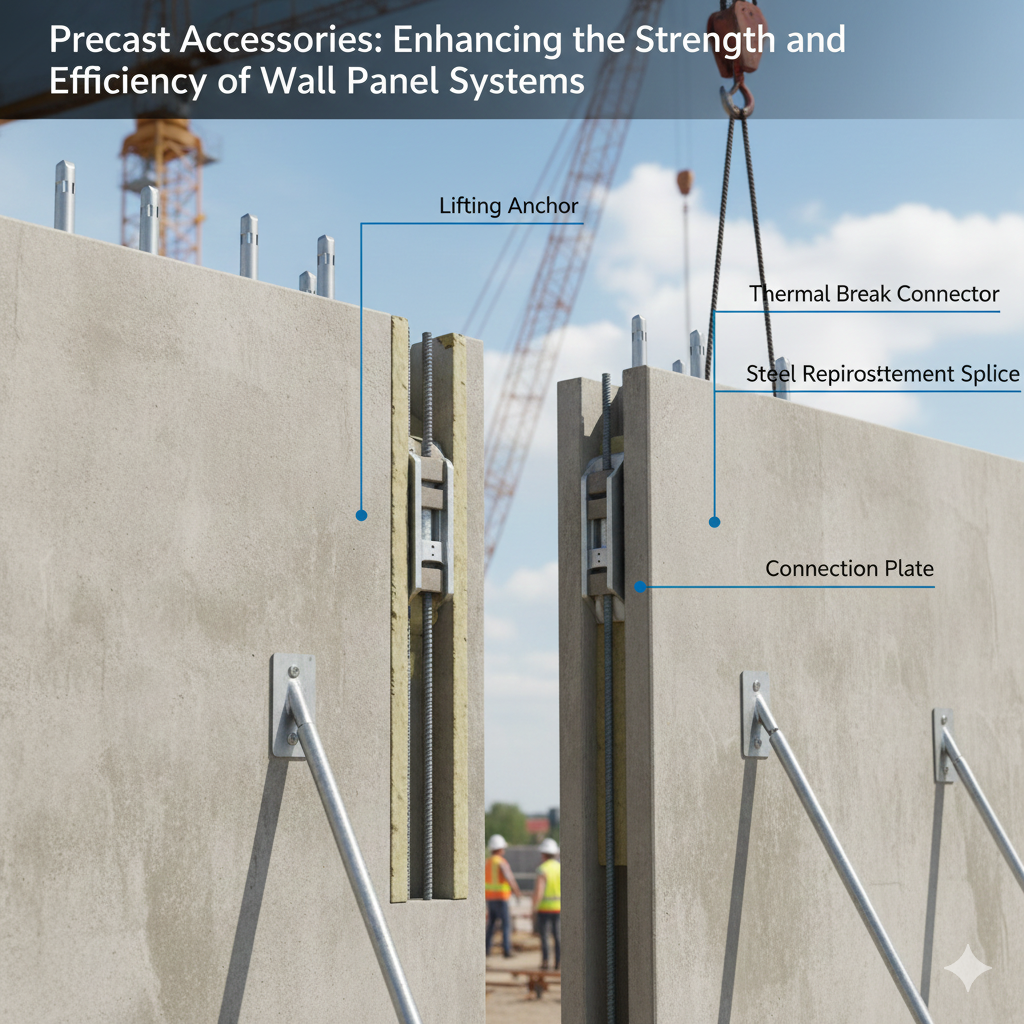

Applications and Versatility in Construction

Pin anchor systems, often employing a compatible ring clutch for lifting, find extensive application across the construction industry, most notably in the precast concrete sector. Their use is prevalent in the manufacturing and installation of wall panels, beams, columns, slabs, and pipes. The ability to securely lift and precisely place these heavy components significantly speeds up construction timelines and improves site safety. The versatility of these systems means they can be adapted for various load capacities and element shapes. Furthermore, the eye anchor variant or other specialized anchors can be chosen based on the specific lifting requirements or the type of lifting equipment available on site, ensuring a tailored solution for each project. The reliability of these anchor systems reduces the risk of damage to valuable precast units during handling.

Advantages and Essential Safety Protocols

Investing in quality pin anchor and ring clutch systems offers numerous advantages. These include increased productivity due to faster handling of elements, enhanced safety by providing secure lifting points, and cost-effectiveness through reusable lifting clutches and efficient installation methods. The embedded nature of the pin anchor also means a clean finish once the lifting process is complete, with minimal patching required. However, the safe use of these systems is paramount. This involves ensuring correct anchor selection for the load, proper installation of the anchor within the concrete (including sufficient embedment depth and concrete strength), regular inspection and maintenance of the ring clutch, and adherence to all manufacturer guidelines and industry safety standards. Training for operatives on the correct engagement and disengagement of the clutch with the eye anchor or pin head is also crucial to prevent accidents. Incorrect use can lead to catastrophic failures, highlighting the importance of diligence and proper procedure.

Conclusion: The Foundation of Safe and Efficient Lifting

In summary, the pin anchor, along with associated components like the eye anchor and the vital ring clutch, forms the backbone of many modern lifting operations in the construction industry, particularly for precast concrete. These systems provide a robust, reliable, and efficient method for handling heavy elements, contributing significantly to the speed and safety of construction projects. Understanding their design, proper application, and the critical safety protocols associated with their use ensures that construction professionals can leverage these tools to their full potential, building structures that are not only sound but also erected with the highest standards of safety and efficiency.